Cider & pig

/This weekend, we hosted our now annual backyard cider pressing. It turned out to be a gorgeous day for it, with perfect fall foliage and a brighteness to the air that made the day sublime.

Did you know that the early spring & late frost back in April or May had a real impact on the price of your apples? I am sure there is probably an apple index somewhere that people interested track this stuff. I didn't really notice, until I went to our local apple farm for our bulk purchase.

Frank Carlson (of Carlson's Orchards) has been growing apples, peaches, nectarines and blueberries for about a million years. He is a classic Yankee farmer: gruff, blunt and pragmatic. Dealing with him is about like talking to Walter Matthau, if Walter Matthau had grown up to be an apple framer. On one of Walter Matthau's less polite days. It's kind of a mix of grunts and dour predictions or memories of weather catastrophes and pest control.

Frank is my kind of people.

He had apples for me, but it was about twice as expensive per bushel as last year. And that was after he gave me a substantial discount. Because he remembers me from year to year, and the time I almost crashed my truck (last year) when the weight of the apples nearly overcame my ability to operate the oh-so-very manual steering and manual brakes on the trip home. I told him that story (and about the state trooper that pulled in behind me to ask what the hell was wrong with my driving as I sat trying to recover my breath on the side of the freeway), and we both had a brief, dry chuckle before we threw more apples in the back of the truck. Because he knows that I'll be back next year, no matter what.

20 bushels looks like this:

At this point, the Carlisle pressing collective springs into action. (I just made that up. There are a few of us who get into this every year, and share tips & tools). The press belongs to my buddy who chairs the town Historical Commission I'm also on. The chipper-cum-apple-grinder is the genius work of another friend in town who is the quintessential yankee tinkerer. After the first year of manually grinding all the apples above with a hand cranked grinder, I cannot say enough about the value of this invention.

But maybe most important gap we had to fill was serving our guests the hard cider from last year's pressing.

I had set aside about thirty gallons of cider to ferment, and had been seriously remiss this summer about putting it up into bottles.

(The process we use is pretty straightforward, but maybe worth another post. The quick version is: press apples; put juice in bucket; add sulfite to kill any bacteria; add yeast back since you just killed off all the bacteria; add some additional sugar to up the alcohol potential (mine tends to be around 9.5-10.5%); seal the bucket; go do something else for a few months until it's ready; bottle; drink; get headache.)

The Critter helped me bottle like mad the couple of nights before the party, and we had a whole basement full, ready to drink before you knew it.

Last year, we had two separate events - cider pressing in the fall, and a pig roast a few weeks before that. Why did we separate them? I can't recall exactly. But it seemed like a good idea to combine the fun this fall. If there's anything I learned from the Brady Bunch, it's that pork goes well with apples.

So I went back to my butcher, Mike Dulock (who recently moved a couple of towns in towards Boston - it's a brilliant new location for him, but a little less convenient for me and my occasional whole-animal needs. Damn you, Mike!) - and ordered a pig.

"How big a pig do you want?"

(One of the signs of a good butcher? Doesn't even blink when you ask for a whole animal. Which really shouldn't be a surprise to a butcher. But in the US these days, it's actually hard to find a place like this).

"Mmm. Somewhere in the 80+ pound range should do us."

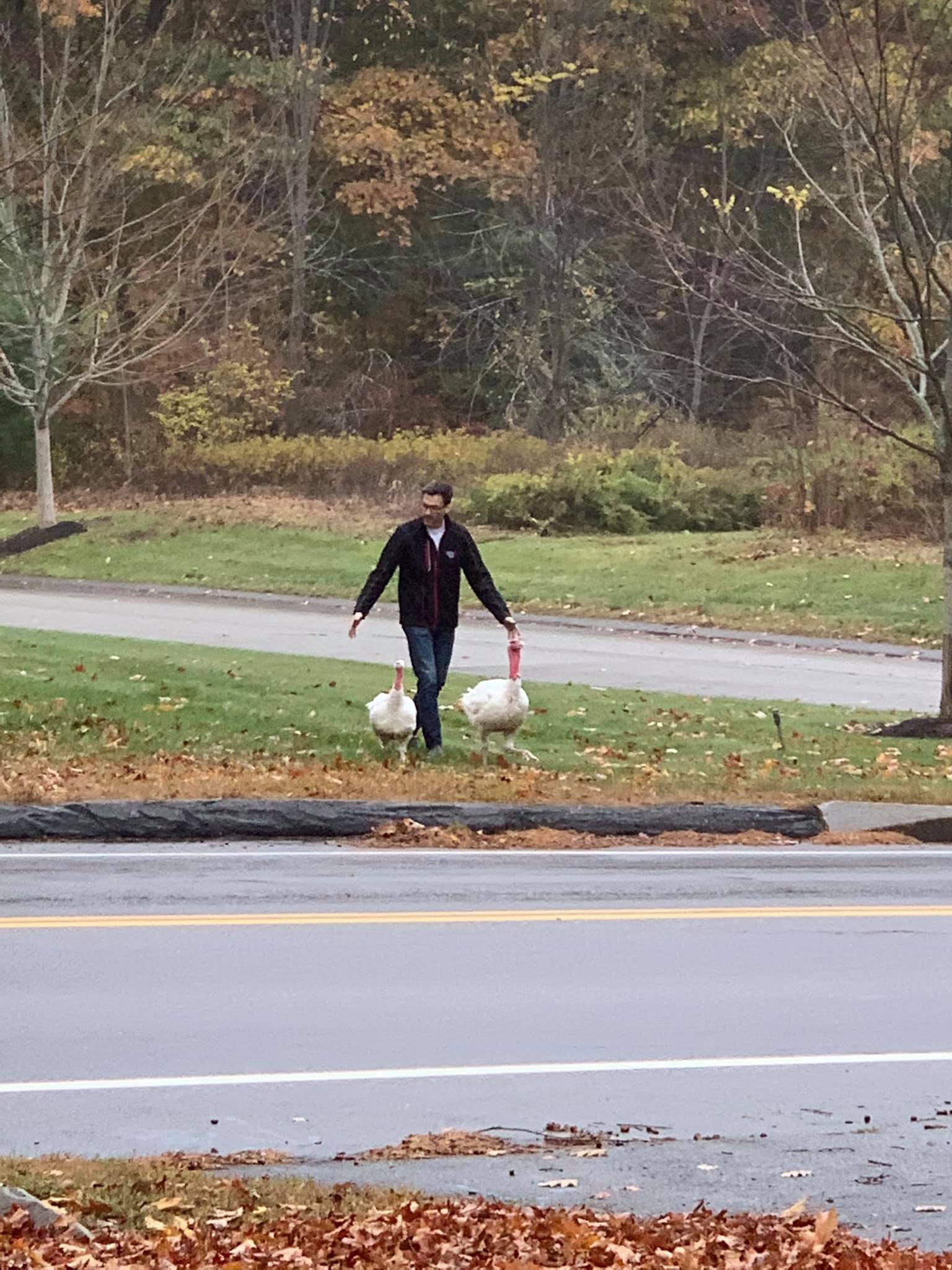

Apparently, the emphasis ended up on the "+" part of that conversation. What we ended up with was Hogzilla.

113 pounds of porky glory. I had them butterfly the pig for roasting (having previously done some extensive research on various schools of pig roast thought) - putting this sucker on a spit would've been quite a chore.

(That's Maureen & Jamal from M.F. Dulock's - great form, guys!)

Getting this home on Friday before the party prompted some interesting discussions in my household. I was at work, and had meetings that I couldn't move too much. So my beautiful Bride volunteered to go pick up our little piggy prize. I offered to let her drive the truck, but she had other errands to do (and doesn't much care to drive the truck into the city. See above's comment on the manual steering and brakes. I don't blame her.) So she had the pig carcass thrown in the back of her Volvo, and took it to pick up the kids at school.

My kids will totally win the group therapy story-telling prize.

As before, I simply scored Wilburina's back with a razor knife in a criss-cross pattern, and briskly rubbed her down with kosher salt. She looked so pretty there in the morning sunlight.

Pretty freaking big, that is.

I let her sit for about an hour while I got the pit up to the right temperature. My goal was to keep the heat around 225 in the pit, and get the meat up to a temperature of 175 or so throughout.

The challenge this year was that the day had dawned pretty cold - the night before had been our first hard frost of the season, and the outside temperature hovered around 50 degrees all day. My oven is just a temporary cinderblock raised "pit", with a rebar grill and a lid made of sheet metal and plywood. It can get pretty warm, but it takes a while to counter the chill in the cement.

With such a big pig, it was something of a balancing act to get it done in time. Last year's pig (around the 85 lb mark) took a little less than 4 hours to cook completely. (Surprisingly fast - but with the pig butterflied, you're not losing all the heat to the internal cavity). I knew that this would take a bit longer, so I admit I let the heat get a little hotter than I might have otherwise. The good thing is, the pig had a nice layer of fat to balance things out, and keep her from drying out.

An important note if you plan on doing this yourself (and you really, really should) - Just line the two sides of the pit with charcoal - there is no need to put any in the center.

I laid her out skin side up, covered her up, and checked on her every half our or so for a few hours.

All told, I used about 3.5 big bags of charcoal to keep the heat going for about 4.5 - 5 hours. I let the heat get up to about 275 or so to accelerate things, and didn't flip the pig until the last half hour. Only then did I push some of the charcoals into the center of the pit, and let the skin get nice and crispy.

Note the finer mesh screen under the pig - I actually had a sheet of this on top and bottom to aid in the flipping. When the pig gets beautifully done, the meat will be so tender that it will easily pull away from the bone - and you really don't want to be chasing the best bits into the hot ashes from the pit.

When I pulled her out, she was still a little undercooked, right at the thickest part of the ham. But that's ok. I had different plans for that part of the pig anyway.

By letting the pig cook a little longer, we had more time to press apples.

This is a shot of the magic grinder in a moment of rare idleness. By this time, the ground apples were pretty much everywhere. In use, there's a bucket underneath the plastic guard to catch the freshly ground apple pulp.

Your basic woodchipper makes pretty short work of an apple, I tell you.

The most frequent question I was asked during the grinding was if you left the stems, seeds and all go in?

Yes, you do. What you're creating is a mash that you can press for juice. I'm not worried about stems and the like, as they don't really contribute any juice. They're just along for the ride so to speak. So just chuck the whole apple in.

As always, the kids really loved the grinding part. Throw stuff in a running woodchipper? Make a mess? What five year old wouldn't be in heaven?

The ground apples go in the press basket. And we move back in time from the electric chipper to the manual screw press.

The big, industrial hydraulic presses can get more than 5 gallons of juice out of a bushel of good apples (40 lbs). On a manual press, you're doing well to get 2-3 gallons per bushel. We do pretty well by letting the apples sit out and "sweat" for a week (in the first picture above) - which allows the cellulose walls to break down, and more juice to come out.

This is also where the hard frost worked in our favor - one, it further broke down the apple to give us more juice. And two, it killed off most of the yellow jackets that have a tendency to swarm all over the press & the fresh, sweet cider otherwise. I only found a couple of very sluggish yellow jackets in the pile of apples this year, and no stings at all.

The sweet brown juice just pours right out - nothing added. Perfect to drink.

Some kids wanted to know the difference between 'cider' and 'juice' - my standard answer is that the apple juice you buy is generally clarified, removing the cloudy sediment. But I've seen the words used pretty interchangeably. I don't think there's a cider police that will take you away if you use one over the other (although alcoholic cider is always called hard 'cider'. Or 'hooch', maybe, if you get the abv up high enough.)

Whatever you call it - a cup full of cider caught cold and fresh as it streams out of the press is one of life's best experiences.

So kids, when you're telling your therapist about the pig carcass that coldly eyed you the whole way home, be sure to also include the story about the fresh cider. We do try and find a balance.

In all, we had around 80 or 90 people out, most of whom got to take a turn at the press and sipping cold or warm cider (we would occasionally bring a fresh gallon in and let it warm up on the stove, to make sure people didn't get too chilled).

That kept the appetites and thirst going - and we served plenty of hard cider, fried chicken and various other goodies that were brought along by our friends and neighbors. One friend brought these amazingly beautiful popovers in flower form - almost too pretty to eat!

By mid-afternoon, the pig was ready to lift out and serve. I tapped a few burly men on the shoulder to come help me heft it out of the grill.

Beautiful - isn't it?

You can see the fresh, clear grease dripping down the wall (and a good view of how simply the pit was constructed).

We lifted this up and brought it to the press like we were lifting up a champion on our shoulders, for all to admire. I guess in a way we were.

Here you can see the excitement on my Bride's face.

This is the girl I love. And why I love her:

Serve with a loaf of Wonderbread - ripped off pieces of crispy, hot, salty skin and juicy meat and you have a perfect sandwich.

In the end, the pig cooked a bit less than 5 hours, with an average pit temperature of about 250-270 degrees F. The hams we cut off and boiled a bit further later in the evening to make brunswick stew for later in the week. There was certainly enough of this porker to go around!

We wrapped things up around dark, and sent folks off with a bottle or jug of cider if they wanted, and a plate full of pork (often whether they wanted it or not). And a thanks for coming out and helping us celebrate the arrival of fall, the New England way. With good friends and neighbors.