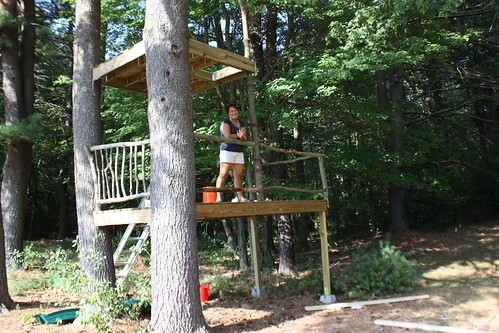

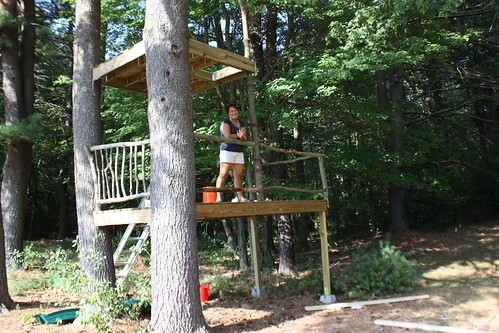

It doesn't have plumbing, but it can pick up the wi-fi

/For about a year, the people I live with had been bugging me about a treehouse.

It didn't start out that way. It started as a "we should think about one of those play structure things." I was quick to stomp on that idea.

Look, I know I'm about to offend all of my friends who own them, but I have never in my life seen an attractive play structure. No, not even yours. In fact, especially not yours. They're just not very pretty. And as much as I get the whole "but the kids love to play on them" aspect, I'm the one who's got to sit on my porch and look out at the damned thing. So no. I'm not getting a play structure.

Of course, trying to Put My Foot Down once my Bride has an idea in her head is about like telling the Iceland volcano that shut down air traffic this summer to get over the whole "ash" idea. A force of nature will not be denied.

I tried enlisting my neighbors in my coercion (they have twin 5 year olds, and have so far resisted the play structure menace as well). I like my lawn. I like my yard. It goes with the house. Let's not mess with that, m'kay?

But then my Bride played the "hey ass, you're not the one who's stuck with the kids all day through the summer. Easy for you to say no," card. Which, you've got to admit, is a pretty low blow. True, maybe, but wicked. And in a moment of weakness, I gave an inch.

"What about a treehouse, instead?"

Holy appeasement, Batman, what the hell were you thinking? This then became, "But Daddy, you promised." Which then led to slippery slope. Which then led to a set of plans being drafted and put on my desk, and appropriate trees picked out.

Read More